Conservation

By Cody Besett

This project involved the digitization of a collection of cassette and reel-to-reel tapes that were recorded during the 1979 and 1980 convention sessions. The age of the tapes made it likely that conservation measures would need to be taken before and, in several instances, as the digitization process was carried out.

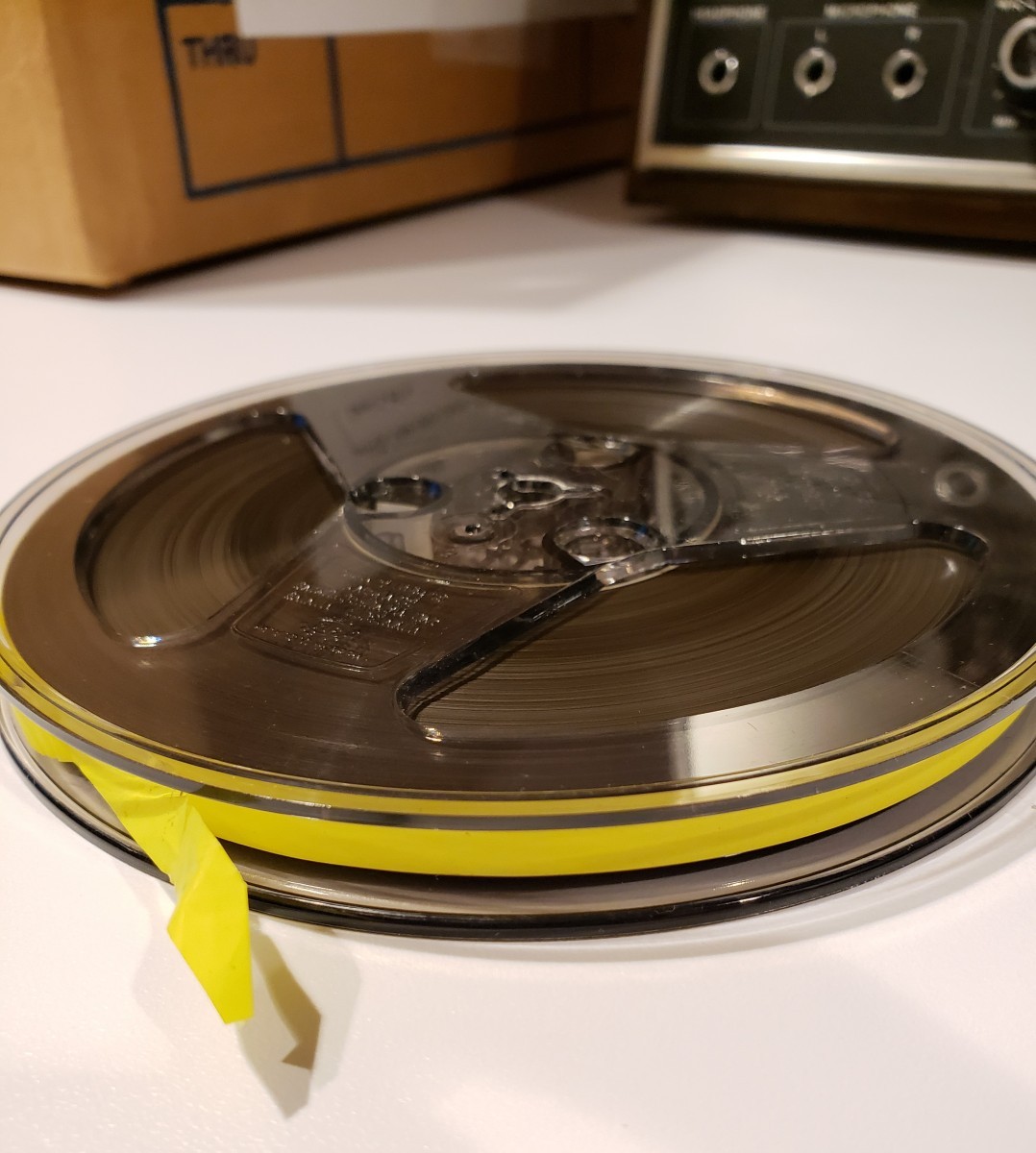

The Center for Arkansas History and Culture (CAHC) received cassette tapes from the Arkansas State Archives in plastic bags. CAHC staff and student digitization workers collected identifying information from the cassette shell labels and examined the tapes for obvious condition issues. The reel-to-reel tapes were CAHC materials, and they were stored in the original Scotch-brand cardboard boxes. Most of the reel-to-reel tapes had uneven tape pack, possibly from improper horizontal storage and decades without use.

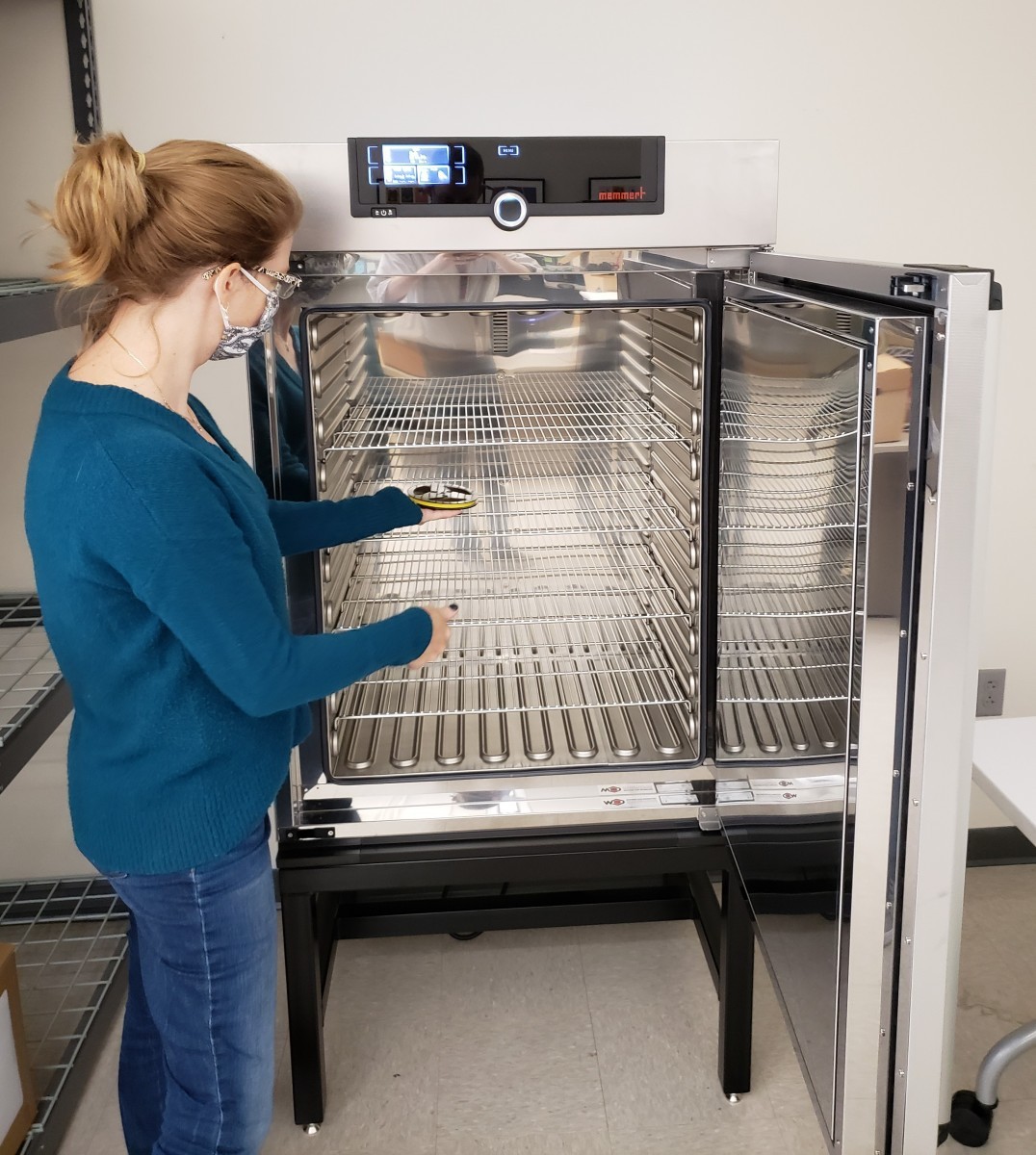

Many of the reel-to-reel tapes exhibited “sticky shed syndrome.” Magnetic tape is essentially magnetic material bound to a plastic base with added lubricant to reduce wear. Over time, the binder may chemically degrade. This degradation can be caused by hydrolysis, a slow absorption of moisture present in the environment. This condition is referred to as “sticky shed syndrome.” If not baked, tapes with sticky shed will stick to parts on the playback equipment and become damaged as the magnetic information is shed from the tape. Baking these tapes temporarily alleviates this chemical breakdown and allows them to be digitized without additional damage.

CAHC’s student workers handled the sticky shed syndrome by baking the reel-to-reel tapes in a special scientific oven. The oven can precisely hold temperature in the 125-135 degrees Fahrenheit range for over eight hours, which is necessary for safe and effective tape baking.

After they cooled from baking, the tapes were wound onto aluminum reels. The aluminum reels assisted in correcting some of the uneven tape packing because they were more rigid than the original plastic reels.

Vintage reel-to-reel and cassette equipment, some manufactured in the mid-1970s, was used nearly forty hours each week for digitization. Even recently serviced, this constant use resulted in breakdowns that required additional servicing or parts. Unfortunately, finding technicians to work on vintage audio equipment was difficult, and arranging for quick and effective repairs was even more challenging.

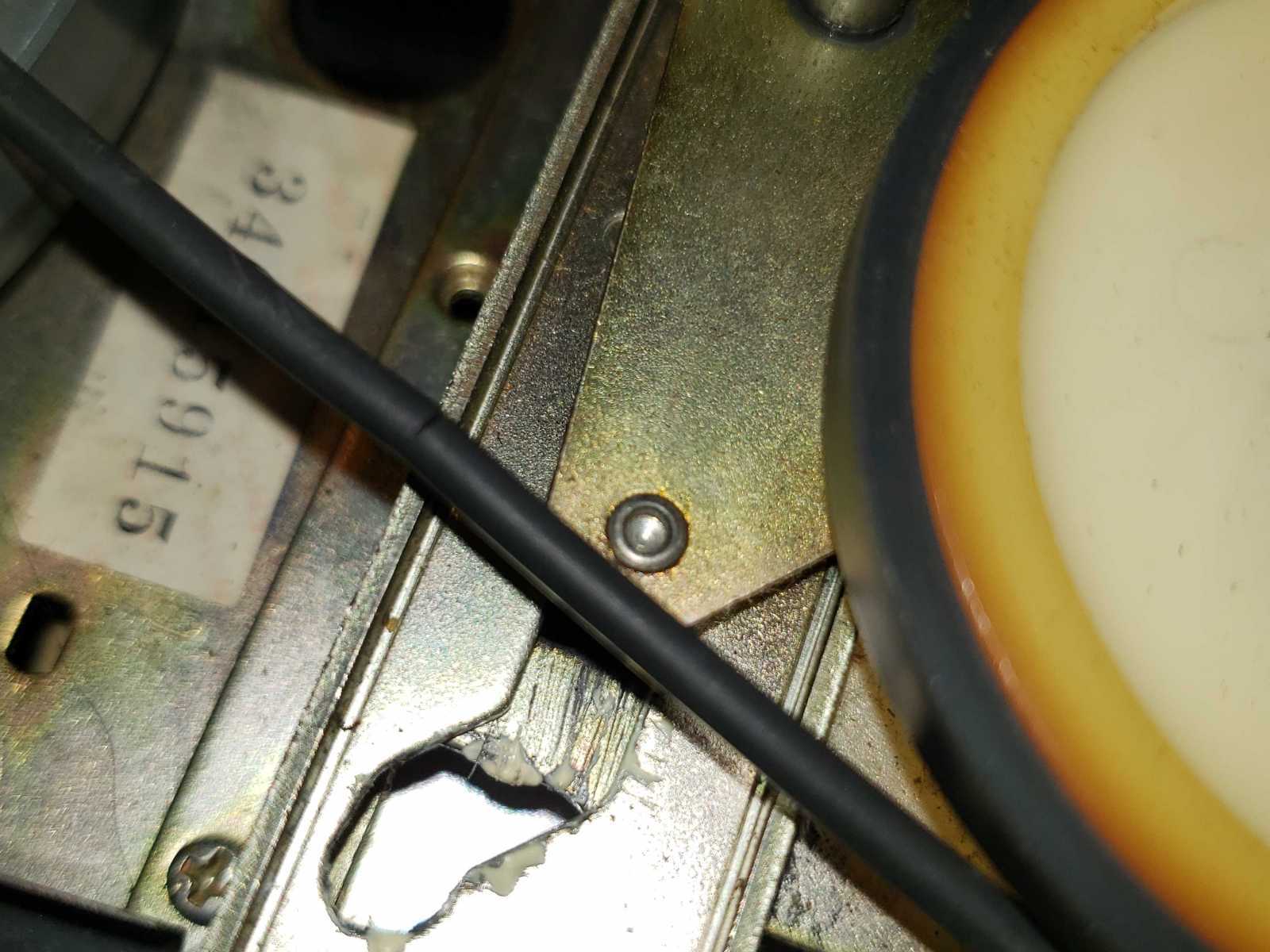

Luckily, staff were able to make some basic repairs onsite using prior knowledge or information that could be gleaned from blogs and tape enthusiast forums. These forums are large online communities of individuals who still use vintage tape equipment and regularly encounter the same issues that affected the equipment used in this grant.

Another problem CAHC staff and student workers faced during the digitization process was speed instability from the cassette and reel-to-reel playback equipment. This problem typically traced back to belt tension. The belts in the cassette decks were at least fifteen years old, and their age and constant use in the digitization process caused them to stretch and lose tension. Staff also had to locate replacement belts for the reel-to-reel deck. Although these belts had been replaced prior to beginning the project, many of the new belts are not made to the same standards and do not last as long as the factory originals.

In addition, the tapes occasionally suffered from condition issues that required replacement parts. Pieces of the nylon takeup reels cracked from age, and the cassette pressure pads occasionally fell out of the shells. These issues had to be dealt with before the cassette tapes could be digitized. To fix the problem, CAHC staff and student workers used a stock of new production Maxell UR cassette tapes to swap out the broken parts with new ones. Occasionally, the poor quality of the shells caused some issues with cassette playback. In cases where it was deemed necessary, they replaced the vintage shell with a new one for smoother tape playback.

To complete the conservation process, CAHC student workers wrote metadata to describe the content of the tapes. That metadata was used to upload the digitized audio files to the Arkansas Studies catalog so the public could access the recordings.

To listen to the audio recordings from the 1979-1980 Convention, visit the Arkansas Studies Research Portal.

Metadata

Descriptive information about a digital object such as its content, creator, date of creation, and file name.

For More Information:

Davis, Andrew. “Towards understanding the thermal remediation of degraded archival reel-to-reel audio tapes.” Morressier. Submitted April 2, 2020. https://www.morressier.com/article/towards-understanding-thermal-remediation-degraded-archival-reeltoreel-audio-tapes/5e736c6bcde2b641284abb13.

“Magnetic Tape Binder Breakdown.” Preservation Self-Assessment Program. Accessed May 5, 2021. https://psap.library.illinois.edu/collection-id-guide/softbindersyn.

About the Author:

Cody Besett is the Student Success archivist at the UA Little Rock Center for Arkansas History and Culture.